Typical challenges in managing supply chain for semiconductor industry

A few years back, the global market for the semiconductor industry was stable and predictable. In a rapidly evolving change scenario, the industry is plagued by different problems such as enhancing revenue growth and profitability, delivering new products that match customer requirements, and ability to manage global operations effectively.

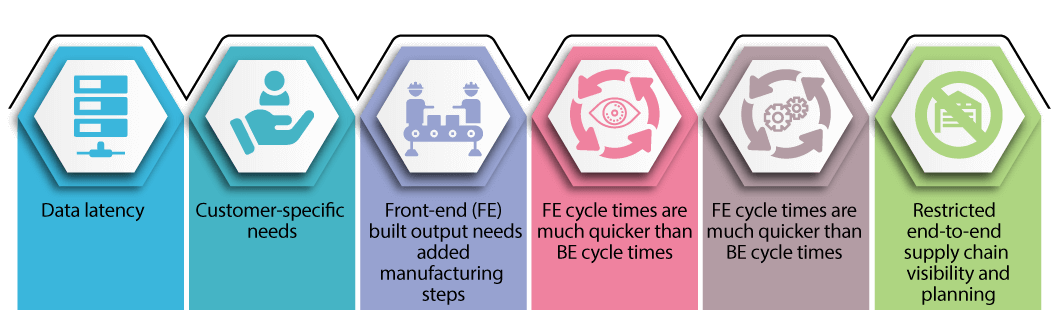

The following are identified as five top challenges the semiconductor supply chain is fraught with:

Data latency

Power, efficiency and task-based binning of wafer-die can lead to different co-products from the sane wafer. Different tasks, each using varied planning parameters, triggers data latency issues since that data is stored in multiple disparate systems.

Customer-specific needs

Often, the same product contains varied material, site, shipment size, quality manufacturing. All such needs tend to be vary as they are based on customer’s specific demands.

Front-end (FE) built output needs added manufacturing steps

FE outputs such as wafers need further manufacturing steps such as assembly and testing as well as a blended model. This results in complexities across the supply chain, turning efficient capacity planning more difficult.

FE cycle times are much quicker than BE cycle times

The processing period of FE cycle is typically 6-8 weeks, whereas BE cycle times are mere 1-2 weeks only. This effectively means deferring inventory at different manufacturing periods, which needs additional planning.

Restricted end-to-end supply chain visibility and planning

Abundant direct and indirect materials needed for manufacturing, and unrelated in-house and contractual manufacturing sites and distribution centers, makes supply chain prominence tough, learning to excess inventory growth and inefficient customer service.

How does the semiconductor industry wriggle out of supply chain issues to improve efficiency and profitability?

Enterprises in technology-based industries are prone to becoming obsolete if they do not address their biggest supply chain challenges and apply perfect resources to deal with problems.

Semiconductor companies adopt a five-pronged approach to manage supply chain issues

- Cost reductions with giving due importance to product quality and delivering products to the market.

- Protection and security for equipment that needs specialized handling.

- Acceleration in the implementation of technology is double time quicker than what the Research Development takes.

- Expansion of product line

- Increases in Mergers and Acquisitions (M &A)

Other challenges faced by the semiconductor industry

Here are some other challenges every industry encounters hurdles in the sector. Some of those main challenges are

- Short product life cycles

- Long production lead times

- Escalation of manufacturing capacity costs

- Continued use of contract services and partnerships lead to complexities when it matters maintaining an efficient supply chain.

Conclusion

Every industry faces distinctive supply chain pain points that would have to be overcome to enhance efficiency and profitability.